ArmorKote®,

The Most Trusted Do It Yourself Pool Restoration System in America!

WELCOME TO THE BEST SOLUTION FOR YOUR POOL RESTORATION PROJECT

DEAR POOL ENTHUSIAST, UNLEASH THE POTENTIAL OF YOUR POOL WITH ARMORKOTE, AMERICAS #1 TRUSTED DIY POOL RESTORATION SYSTEM

Why Choose ArmorKote?

Unrivaled Quality

Discover a new standard of performance and quality with our pool restoration materials. Crafted from premium, durable components, our coatings are all produced as 100% solids and are engineered to withstand the rigors of time, weather, and regular pool use. When you choose ArmorKote, you're choosing lasting quality.Innovative Solutions

Stay ahead in the world of pool restoration with our cutting-edge materials. We continuously invest in research and development to bring you innovative solutions that enhance the beauty and functionality of your pool. Our performance industrial coatings aren't just products; they're a testament to progress and modernity.Unrivaled Quality

If you’ve spent any time at all getting quotes for a pool restoration project, you know it can quickly exceed $10k. With ArmorKote, you’ll save thousands, and ultimately be more satisfied than if you’d spent more money.Common Concerns

Are These Materials Easy to Work With?

Indeed, they are. Our materials are designed with both DIY enthusiasts and professionals in mind. Clear instructions and user-friendly features make installation a breeze, ensuring a smooth and successful pool restoration experience.We have designed the ArmorKote system so that it does not require any secondary and/or toxic solvents to be added to the material before application, and the VOC content is so low there is no need to suit or mask up when applying.

Can I Trust the Quality

Absolutely. Our commitment to quality is unwavering. We source the finest material components to ensure they meet and exceed industry standards. When you choose ArmorKote, you're choosing reliability, durability and a commitment to excellence.WHY ARMORKOTE OUTPACES OTHER RESURFACING OPTIONS.

SUPERIOR TO FIBERGLASS GEL COAT

While fiberglass gel coat has its merits, it is extremely difficult to apply in non-controlled manufacturing environments. ArmorKote offers a unique blend of durability and customization. Unlike fiberglass gel coat, it is easy to apply in uncontrolled environments, it is not prone to cracking, and there is a broad range of color options to suit your aesthetic preferences.OUTSHINING POOL PAINT

Pool paint may offer a quick fix, but it lacks the durability and long-term appeal of a true performance industrial coating. ArmorKote applies 5X thicker than most pool paints and ensures a lasting, vibrant finish that withstands the challenges posed by chemicals, weather, and regular use.Beyond Traditional Plaster

Traditional plaster may be common, but ArmorKote surpass it in longevity and aesthetic versatility. Truth be told, as soon as a plaster pool is filled with chemically adjusted water the chemicals immediately go to work to break down the plaster. Say goodbye to frequent re-plastering – ArmorKote has been engineered to withstand chemical impact without compromising on style and aesthetics.Begin Your Project Now!

BUY NOWWhy ArmorKote Stands Out Against Competitors

Outperforming EcoFinish

While EcoFinish may have its merits, it requires special equipment to apply and is very expensive. Homeowners who have chosen to go this route are starting to experience a failure rate not anticipated. The ArmorKote pool restoration system is designed as a true performance industrial coating and stands out with a superior combination of durability, versatility, and aesthetic appeal. ArmorKote ensures a longer lasting and more visually impressive pool restoration.Surpassing Aquaguard 5000

Aquaguard 5000 is a notable contender, but the ArmorKote pool restoration system takes the lead with advanced technology. The system was produced with user friendliness and environmental concerns in mind. With Armorkote, the user is not required to work with and add toxic solvents into the coating mix and the VOC content is so low that there is no requirement to suit or mask up before applying.Exclusive Offer for Pool Owners

Fill out our pool resurfacing questionnaire to get 10% off your purchase.

For a limited time, we're offering an exclusive 10% discount on our premium pool restoration products. Restore your pool back to its original beauty with ArmorKote and enjoy the benefits of a revitalized aquatic paradise.BEGIN NOW

READY TO ENJOY THE BENEFIT OF HIGH PERFORMANCE?

Here's to transforming your pool into a masterpiece!

Sincerely,

KoreKote - Advanced Epoxy Systems

Armorkote Pool Restoration System

#1 DIY Pool Restoration System In America

Armorkote Pool Restoration System

POOL RESTORATION SYSTEM

#1 DIY Pool Restoration System In America

$660.00-$4776.00

SKU 58000

Step 1 - Choose Pool Substrate

Quantity

NOTE: (BASEKOTE) – 1 unit (3 gallons) covers a max of 500 sq/ft , (ARMORKOTE) – 1 unit (3 gallons) covers a max of 300 sq/ft

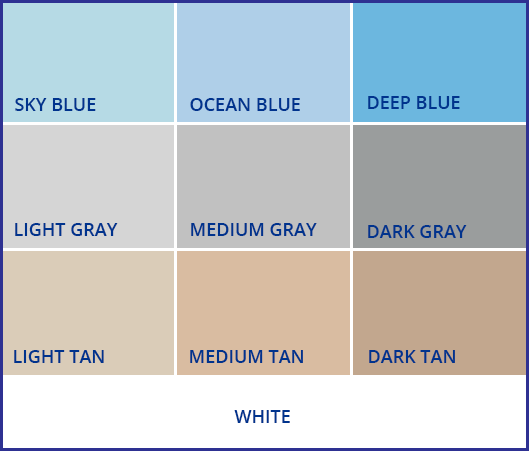

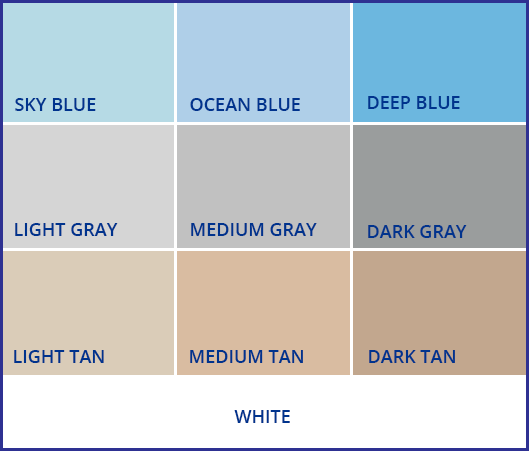

Available Colors

ArmorKote Pool Restoration System

A perfect pool requires a perfect

coating.

A perfect pool requires a perfect coating. ArmorKote features the best chlorine and chemical barrier on the market. It’s also America’s leading pool repair and resurface coating material. Not only that, but it’s antibacterial, antifungal and environmentally safe. We really did mean perfect.

Welcome to the next level of coating innovation.

When we set out to advance epoxy resin technology, we knew we had to start at the foundation. So we looked at the chemistry behind the material and discovered ways in which it could be improved. The result—SafeResin™. Safer, Stronger, Faster, and Easier. The resin technology that is anything but ordinary.

Key Attributes

- UV stable

- Engineered with SafeResin

- Outstanding chlorine and chemical barrier

- Extra strong 40ml coating (Two Coats)

- Maximum bond strength

- Ultra low vocs and no foul odors

- Mildew inhibiting

- Self leveling for easier application

- 5 Year Warranty

- Low environmental impact

- Non-permeable surface

- Fully cured 24-48 hours (at 70°F)

- Easier to apply/clean up than paint

- Trusted by America’s largest corporations

- America’s preferred pool surface coating

Available Colors

Recommended Substrates

- Concrete

- Marcite

- Gunite

- Fiberglass

- Marble

- Acrylic

Simple Four Step Application

Surface Prep

If any cracks or holes are visible fill them with BONDKOTE, our all-purpose mastic & filler. Etch/sand entire pool surface.

Korekote BondKote

NOTE: Sold Separately Form System Kit

KoreKote Surface Cleaner

Use cleaner to remove residue and/or blushing. Surface cleaning also provides a surface etching in preparation for sealing and bonding.

KoreKote BaseKote Primer

Seals and bonds entire substrate. Provides strong hydrostatic back pressure barrier. Cures to substrate completely clear and gives you 40% more bond strength than ordinary primers.

ArmorKote

A simple roll on epoxy coating that features the best chlorine and chemical barrier on the market. It’s also America’s leading pool repair and resurface coating material.

System Kit Includes

KoreKote Surface Cleaner

1 container

Covers 1000 sqft

Removes residue and/or blushing and provides surface etching in preparation for sealing and bonding.

Korekote BaseKote

3 gallons

(1.5 gals resin/1.5 gals hardener) = Coverage of 400 sqft (Coverage will vary based on substrate and condition)

Seals and bonds entire substrate. Provides strong hydrostatic back pressure barrier. Cures to substrate completely clear.

KoreKote Basecoat

Technical

Data Sheet

DOWNLOAD

ArmorKote

3 gallons

(2 gals resin/1 gal hardener) = Coverage of 300 sqft

Provides industrial grade high end epoxy surface finish.

ArmorKote

Technical Data

Sheet

DOWNLOAD

ArmorKote

POOL RESTORATION SYSTEM

Instructions & SAFETY

Simple

preparation and easy to apply

Surface Preparation

Cleaning

All application surfaces must be free of all dust, dirt and grease. For highest bond strength, chemical cleaning is required before applying pool restoration coating system. Use KoreKote Surface Cleaner® that is included in your system to clean your pool surface.

Cracks and Divots

To fill those tough holes, cracks and divots we recommend using KoreKote BondKote (Not included in system). This mastic product has been specifically formulated to meet the requirements as a high performance filler and bonding agent providing a smooth surface to coat over.

Mixing

ArmorKote

Mix 2:1 ratio by volume of Part A (resin) and Part B (hardener) together. Mix thoroughly until uniform color and consistency throughout. Mechanical Stir Stick (drill with mixing paddle) is recommended.

BaseKote

Mix 1:1 ratio by volume of Part A (resin) and Part B (hardener) together. Mix thoroughly until uniform color and consistency throughout. Mechanical Stir Stick (drill with mixing paddle) is recommended.

Potlife

Potlife of mixed coating is approximately 20 minutes at 70˚F if material is left as a unit in mixing container. Higher temperatures reduce potlife and accelerate curing.

CAUTION: Mixing large quantities (more than a 3 gallon batch size) generates significant heat and shortens potlife.

Application

ArmorKote & BaseKote

Begin by pouring mixed material in a straight line 2 – 3 feet from the desired starting edge of the area being coated. Use lint free 3/8” nap roller on roller frame and spread material evenly over surface. Use brush to do cut-ins along edges and corners if necessary. When material is spread out in a thinner layer, the worklife is extended to approximately 35 minutes (do not apply in temperatures below 50°F).

Curing

Allow coating to cure at 50˚F or higher.

Curing profile at 70°F

- Gel time: 40 minutes

- Crystallized: 4 hours

- Extra strong 40ml coating (Two Coats)

- Cured: 24 – 48 hours (depending on temperature and application)

Clean Up

Use denatured alcohol (not necessary to use harmful/toxic solvents) to cleanup uncured material and tools.

Safty

Precautions

Avoid contact with eyes and / or skin. Wash thoroughly after handling. Provide adequate ventilation to control vapor. KEEP OUT OF THE REACH OF CHILDREN.

SUGGESTED FIRST AID

IF SWALLOWED: Rinse mouth. Do NOT induce vomiting. Call a POISON CONTROL CENTER if you feel unwell.

IF IN EYES: Rinse cautiously with water for several minutes. Remove contact lenses, if present and easy to do. Continue rinsing. If eye irritation persists: Get medical advice. Immediately call a doctor.

IF ON SKIN (or hair): Take off immediately all contaminated clothing. Rinse skin with water or shower. Wash contaminated clothing before reuse. If skin irritation or rash occurs: Get medical attention.

IF INHALED: Remove person to fresh air and keep comfortable for breathing. Immediately call a doctor.

HANDLING SAFETY

Prolonged exposure to Part A (resin) may cause allergic skin reaction on sensitive skin and possible respiratory tract irritation. Prolonged exposure to Part B (hardener) may cause an allergic skin reaction on sensitive skin..

Safety Data Sheets (SDS)

KoreKote Surface Cleaner SDS

DOWNLOAD

KoreKote Basekote SDS

DOWNLOAD

KoreKote Basekote HARDENER SDS

DOWNLOAD

ARMORKOTE RESIN SDS

DOWNLOAD

ARMORKOTE HARDENER SDS

DOWNLOAD

ARMORKOTE LIMITED 5 Year Warranty

This Warranty is offered by KOREKOTE®, referred to as “Manufacturer”, to the original purchaser of ARMORKOTE®, hereinafter referred to as “Buyer”, and is subject to the following terms and conditions:

1. COVERAGE

The authorized ARMORKOTE® Applicator identified in this certificate warrants that the pool described herein has been coated by the Applicator with the ARMORKOTE® polymer, two part epoxy resin finish coat system in full compliance with the Manufacturer’s recommendations and specifications and contains solely those undiluted products recommended and provided by Manufacturer for application to the pool shell identified herein. Manufacturer warrants the ARMORKOTE® against cracking, blistering, peeling or detaching from the outermost surface material to which ARMORKOTE® was originally applied by Applicator for as long as the original Buyer owns the pool within the warranty period. Coverage under this Warranty shall extend only after Applicator and Manufacturer have received payment in full for the services and materials provided to Buyer.

2. LIMITATIONS AND EXCLUSIONS

Manufacturer does not warrant against: · Damage to or failure resulting from any attachments to the pool such as fittings, skimmers, piping, lighting fixtures, wiring, rails, ladders, slides, jump boards or any other accessories. · Damage to or failure resulting from any attendant structures to the pool such as decks, waterfalls, fountains, or spas. · Damage to or failure resulting from concrete decking or other structure attached to the pool shell. · Failure resulting from improper or unauthorized draining of the pool or the rising of the ground water table above the pool water level or pool pop up. · Failure resulting from improper installation. · Any consequential damages, such as, but not limited to, pool water loss, chemical replacement, or other losses, which may arise due to structural failure. · Repairs made by any other party other than an authorized representative of the Manufacturer. · Labor costs of any kind. · Fading, staining, discoloration or in any manner changing the appearance of the top coat surface. · Discoloration or deterioration caused by abnormal use of the pool, improper water chemistry, mineral-laden water, ancillary equipment servicing the pool, or negligence. · Any damages caused or contributed to by accident, negligence, abuse, misuse, act of God, or act of nature (including, but not limited to, flooding, fire, settling of soil, or shifting of earth) or other conditions beyond our control. · Any damages caused by Buyer’s failure to provide reasonable and necessary maintenance to the pool. The Applicator and Manufacturer assume no liability for any bodily injuries resulting from the installation of the coating product. Under no circumstances shall the Applicator or Manufacturer be liable to the Buyer or any other person or entity for any special or consequential damages, whether arising out of breach of warranty, breach of contract or otherwise. Some states may not permit some exclusions or limitations of incidental or consequential damage, therefore, these limitations may not apply.

3. NOTIFICATION

In the event of discovery of a potential Warranty claim condition, Buyer must notify Manufacturer within fifteen (15) days of discovery in writing. Such notification must be sent via registered U.S.P.S. mail to the address listed on this Warranty.

4. PERFORMANCE

Subject to the conditions herein contained and within the warranty period and in the event of failure caused by faulty materials, Manufacturer (or its authorized agent) shall provide replacement pool coating material sufficient to remedy the failed area. Such replacement of the product originally installed shall be the sole remedy within the Warranty period and replacement product will ship FOB the manufacturer’s plant.

5. VOIDING OF THIS WARRANTY

The pool is designed to remain full of water at all times and the coating is designed to remain submersed. This Warranty shall be considered null and void in the event of drainage of the pool below the skimmer outlet. Do not drain the pool or allow any unauthorized person to drain the pool.

6. TRANSFERABILITY

This Warranty extends only to the original Buyer of the pool within the warranty period and is non-transferable or assignable.

7. THIS WARRANTY IS EXCLUSIVE.

THERE ARE NO WARRANTIES EXTENDING BEYOND THOSE DESCRIBED IN THIS DOCUMENT, EITHER WRITTEN, ORAL, OR IMPLIED. THERE IS NO

8. WARRANTY REGISTRATION

The attached Warranty Registration Card must be completely filled out by the Buyer and Applicator and returned to the Manufacturer within fifteen (15) days of the application of the final ARMORGUARD 3300® surface finish coating. Failure to return the Warranty Registration Card will render this Warranty null and void.

9. DISPUTES

All parties to this Warranty agree that any and all disputes that may occur regarding the performance of this Warranty shall be settled by binding arbitration conducted pursuant to a recognized arbitration association selected by Manufacturer. All parties agree that the arbitration proceedings to resolve any and all such disputes shall be conducted in the city where the Manufacturer is located.

RECOMMENDATIONS:

You may notice that your ARMORKOTE® surface coat will require less maintenance and a reduced amount of pool chemicals. Please maintain the following pool chemistry: CHLORINE 1.5 – 2.0 ppm, ACIDITY 7.4 – 7.8 pH, ALKALINITY 90 – 120 ppm, CALCIUM 250 – 350 ppm, STABALIZER 60 – 90 ppm. When initially filling the pool and before the filtration system is started up, a sequestering agent should be used to suspend any mineral particles. PRECAUTION: Please DO NOT allow tri-chlor powder, tablets or stabilizers to settle directly on the surface as this may result in staining or discoloration of the ARMORKOTE® surface.

ArmorKote Customer Testimonials

This is the second time I have refinished my pool. The first time I used another product and after all the work it failed in about 4 years. This time I avidly researched the product and after seeing what was available, choose to use UltraGuard. Not only did I get step by step instructions but also a live coach to help me with the installation. I am impressed. This material is tough as nails, went on as advertised, looks great... I recommend this to everyone!

JACK BROOKS

DIY RESIDENTIAL Project, FL

Please find the pictures of our pool using your product “ULTRAGUARD”. It turned out good. All leaking of the pool has stopped using your system. Our condominium members are thrilled with the appearance. I would definitely recommend your product to anyone who has similar problems. All the claims and benefits of the UltraGuard product are true.

DAVID PARFITT

CENTRAL COAST PROPERTIES, CA

I am the Director of Operations of a major International Plastics Manufacturer. I have been in the Plastics Industry for 24 years. Knowing the properties of plastics, and their chemical resistance and my research into UltraGuard, I believe it is the best swimming pool interior on the market today. I would be happy to speak to you if you are considering UltraGuard.

KEVIN GREVERA

DIY RESIDENTIAL Project, FL